- Gat no 155/3, Arvi Village,

Near Khed Shivapur, Pune 412 205 - marketing@studcraft.com

+91 8767864659

One Stop Solution For of all types of Weld Studs and Special Fasteners

Stud Craft (India) Pvt. Ltd. is engaged in manufacturing of Weld Studs, Special Fasteners and other Engineering Components since 1981.

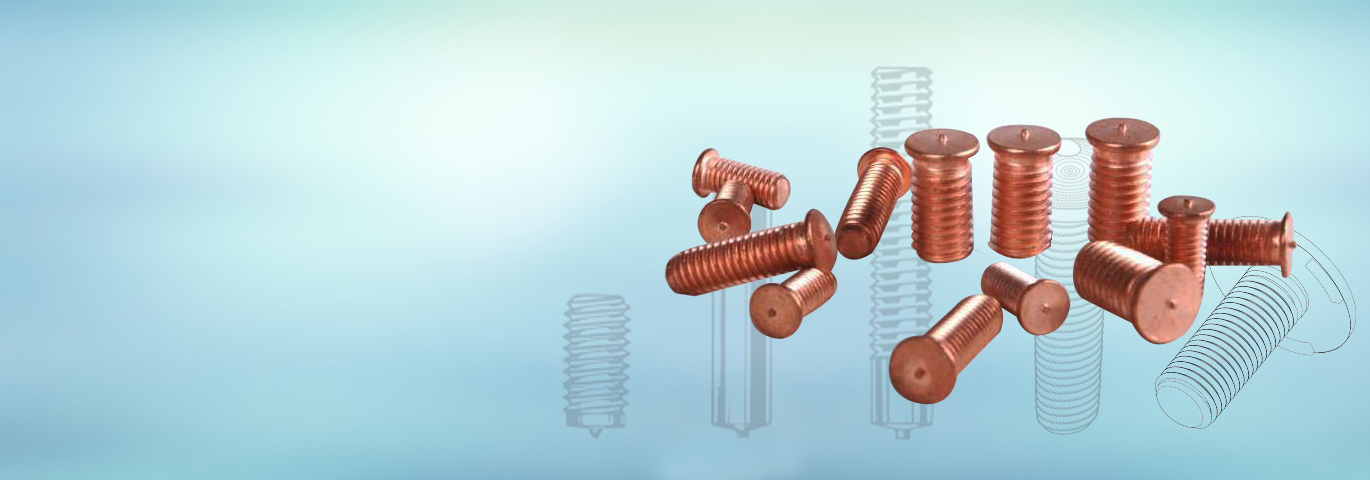

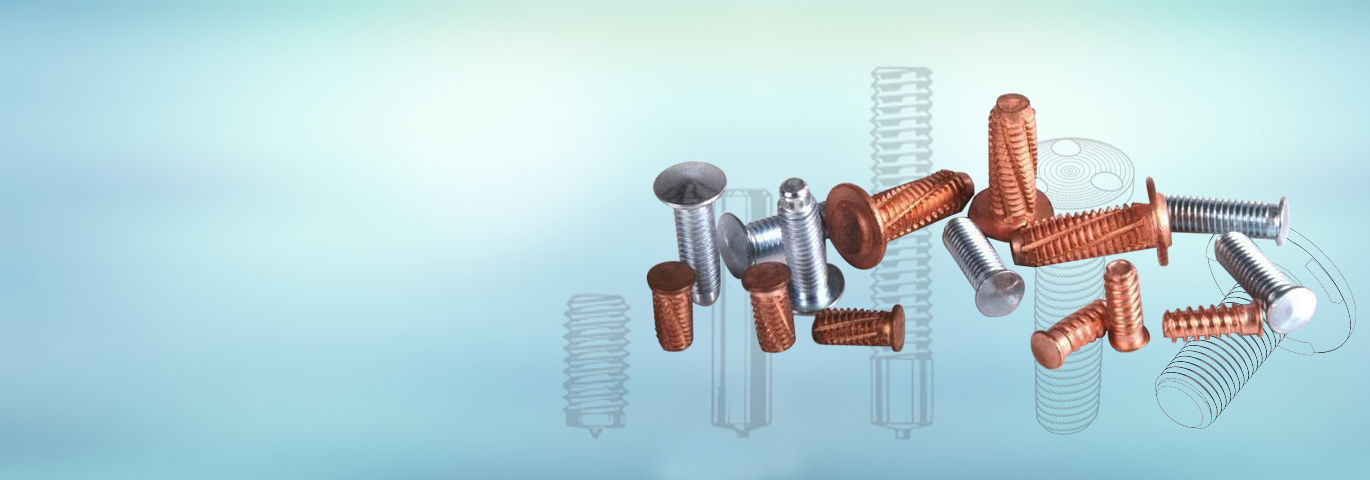

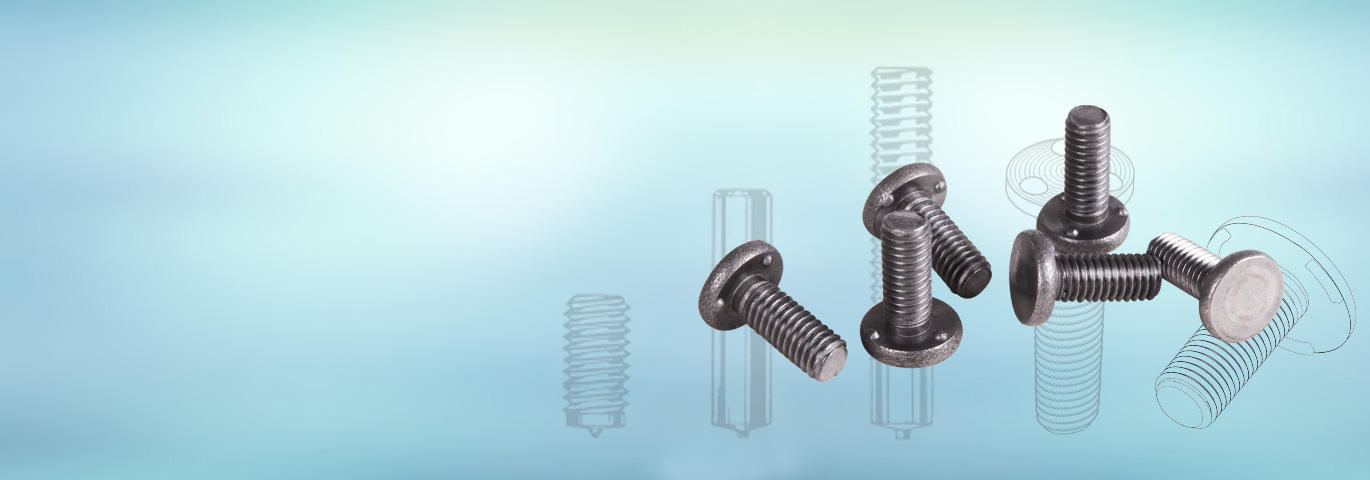

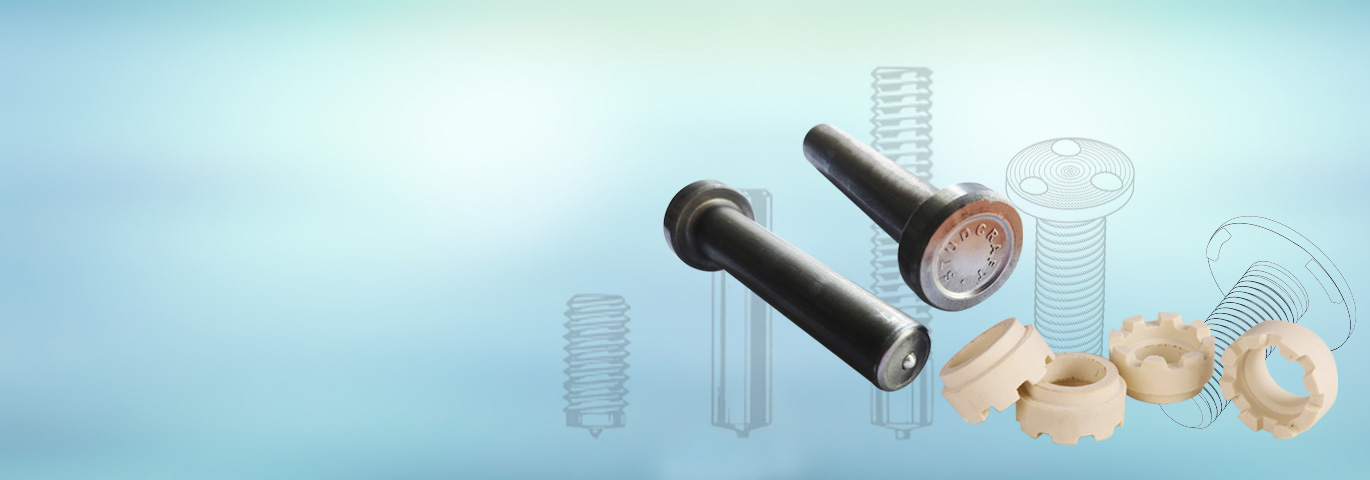

Weld Studs, being our main product, is manufactured in all varieties – Drawn Arc, Capacitor Discharge, Short Cycle – in different materials and dimensions to suit customer's requirement.

We manufacture of all types of Weld Studs and Special Fasteners which are widely used in Construction, Boiler, Transformer, Automotive and other industrial applications.

Stud Craft (India) Pvt. Ltd. is engaged in manufacturing of all types of Weld Studs and Special Fasteners which are widely used in Construction, Boiler, Transformer, Automotive and other industrial applications.

STUDCRAFT is having 2 units located near Khed Shivapur which is around 25km from Pune city. In order to cater to different requirements of various customers we are having state-of–the-art manufacturing facilities.

Also In order to keep a check on the quality of products as well as of Raw Material, we are having in-house inspection facilities

We nurture every customer relationship with commitment, passion and integrity. We believe in converting business relationships into really long-lasting partnerships. Please find below, just a glimpse of some of our customers.